Safety on the road takes many forms. Driving carefully at all times is one of the major ones. For caravanners and motorhomes, there is also the issue of exceeding payload and dealing with the alphabet soup of GVM, ATM, GCM, TBM and tare mass, among others. There's personal safety too, but fortunately, with a bit of care, in Australia that's not such a big problem.

Electrical and gas systems are another matter because recreational vehicles (RVs), whether towed or self-powered, are very sophisticated these days, particularly the electrics. But a few basic precautions will ensure safe RV travel at all times.

Before I proceed further, I should mention a caveat. Under Australian and state laws, just about any electrical or LP gas work, besides things like changing fuses, must be undertaken by a licensed person. There are a few exceptions to this. While any mains (240V AC) work requires an appropriate licence, 12V DC systems can be worked on by a competent do-it-yourselfer. I stress the word competent because 12V DC systems are becoming quite complex and a mistake could be expensive. One of the complexities is inverters; while the input is 12V DC, the output is 240V AC. Another is that battery voltages are rising too; 12V DC is the automotive standard, but there’s an increasing number of 24V DC, 48V DC and 51V DC systems so you need to know your way around such systems. The home mechanic can't legally work on anything over 100V, they should avoid big power lithium batteries.

ELECTRICAL CARE

In both Australia and New Zealand, all electrical wiring work in just about anything that stands or moves is governed by AS/NZS 3000: 2018 for the most part and AS/NZS 3001:2008 to a lesser extent. I only mention that because the standards cover fixed installations like a house or factory and moving installations like a caravan or motorhome. It's ironic that a potential electrical problem, like a loose connection, may exist in a house for years but never be detected because the place never moves. However, in a caravan, guess what? The first road bump will highlight a problem.

Generally speaking, there’s little electrical maintenance required in an RV wiring installation. The problem is more likely to be a component breakdown. An example of why a licensed electrician must work on the 240v system might help. One common issue is power socket switches. Sometimes they break with constant use and that normally requires a new socket. There's a trap here for those not in the know. All power points in an RV are required to be double pole switched. That is, both the active and neutral wires need to be switched. That avoids a potential problem when using an extension cord where the active and neutral connections have been unintentionally reversed in the plug or socket. Hence a double pole power point should never be replaced with a single pole outlet. But if you wrongly wire up any 240V connection it can cause injury or death.

POWER LEADS MATTER

All power leads used to connect RVs to a 240V mains supply should be rated at 15A because the power supply from a single lead might not cope if all caravan appliances are operating at once. The easiest way to tell this is by looking at the plug or socket. The difference between a 15A plug/socket and a household 10A plug/socket is that the earth pin (the non-angled pin) is wider on a 15A plug. At the risk of stating the obvious, it's a silly idea to file down the 15A earth pin to fit a 10A socket for a home connection to fire up the fridge. A better idea is to purchase an approved device like an Ampfibian 10A to 15A adaptor with a built-in circuit breaker – plus, it’s fully waterproof.

One of the biggest problems in any caravan or motorhome electrical setup is usually associated with the 15A power lead. Unfortunately, there are more electrical accidents and fatalities with power leads than just about anything else. Power leads used for RVs are prone to damage mostly because they are frequently on the ground. Keeping the power lead out of harm’s way and away from wet areas is always good. Also, avoid keeping them anywhere crossed by road vehicles.

Power leads are kept neat when stored

Power leads are kept neat when stored

Another little problem can be caused by a home handyman who drills into an RV body to fit something and drills into a 240V cable simultaneously. Besides being a safety issue, it's all costly to fix!

TAGGING AND TESTING

Keeping your power cord(s) in prime condition is vital. ‘Tagging and Testing’, that is, getting a power lead inspected and tested regularly is a good idea. This needs to be done by a competent person, i.e., someone who has done the required training – it doesn't have to be a licensed electrician – and it doesn't take much time.

Part of the ‘Tag and Test’ is a visual check on the power cord insulation and that can be done easily by anyone with a good pair of eyes. It's simply a visual check on the cable insulation's outer sheath to ensure there are no nicks or other insulation damage. It's also appropriate to visually check the plug and socket. If any insulation damage or, worse, bare copper shows, the power lead should be replaced. Some plugs and sockets these days are made of clear plastic and it's straightforward to check if all the wires are correctly connected.

Any sign of heat or burn damage is something else to check for on the plug and socket. If there is anything like that, then the component should be replaced. Unfortunately, burn damage can't be undone and can worsen the problem. If heat damage is noticed, whatever plug or socket the burnt item was connected to should also be checked and replaced if necessary.

To avoid heating issues with the power lead, it's always best to have it fully uncoiled when plugged in. Excess power lead length can always be placed out of the way under the RV.

RESIDUAL CURRENT DEVICES

RVs and caravan park switchboards are fitted with Residual-Current Devices (RCDs). Otherwise known as an earth leakage circuit breaker or ‘safety switch’, they are designed to operate quickly should anyone come into contact with a ‘live conductor’. RCDs have a test switch, which should be operated periodically to ensure it's working correctly.

GAS SYSTEMS

Liquid Propane Gas (LPG) systems are very common in caravans. Devices that use LPG are cooking appliances, fridges, water heaters, space heaters and barbecues. Like electrical installations, gas systems also have an Australian standard in AS/NZS 5601.1:2022 and that effectively means that a licenced person should repair or maintain any gas system. LPG does not have a 12V equivalent!

A few safety dos and don’ts are associated with a gas installation in an RV. In particular:

- Gas cylinders must not be installed or used inside an RV.

- Gas cylinders must be firmly secured and the valves accessible for easy operation.

- Gas compartments need to be sealed off from the inside of an RV, only used for gas cylinders and nothing else and be vented to the outside atmosphere.

- Out-of-date gas cylinders should not be used. There is a date stamp on the bottle and after 10 years it must be retested and stamped with a new inspection date.

- RVs should have adequate ventilation and those same vents and flues should not be blocked.

- A cooking appliance is not a heating device. Gas heaters are purpose designed such that exhaust gases are vented to the outside the RV but cooking appliances rely on general ventilation.

- When travelling, all gas cylinder valves should be closed.

GAS LEAK TESTING

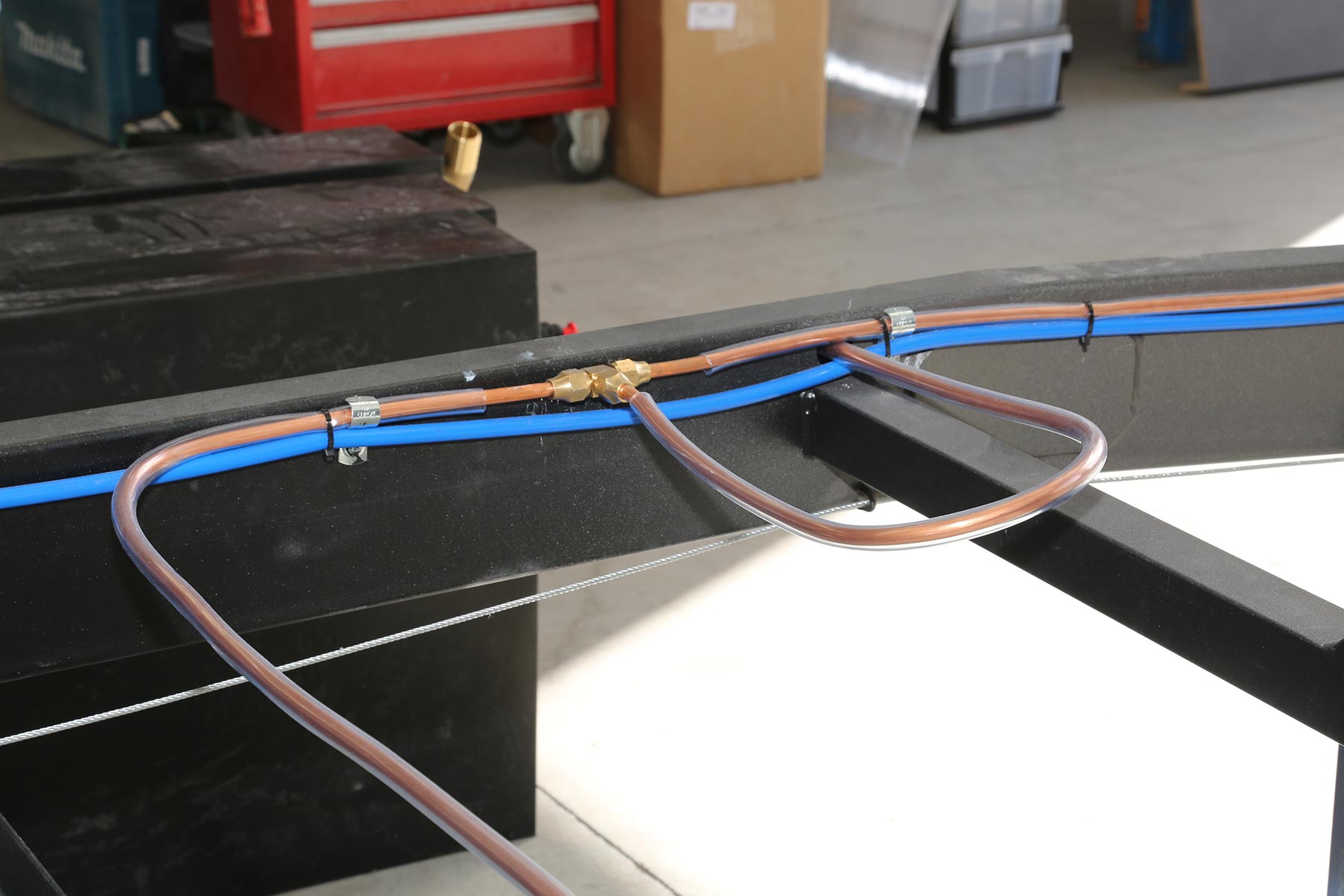

Something that anyone can do is test for a gas leak. If one is suspected – and your nose often gives a clue because LPG does have a distinctive smell – then a test is quite simple. All that's required is very soapy water sprayed onto a suspect hose or connection. If there's a leak, the soapy solution will have apparent bubbles. If the leak is something other than a loose connection, then it's time to seek professional help.

GAS DETECTORS

In a confined space, like an RV, two types of gas are a problem. LPG is one and Carbon Monoxide (CO) is the other. A build-up of LPG can lead to an explosive atmosphere, whereas a build-up of CO, caused by the combustion of LPG, can lead to asphyxiation and be fatal. While LPG can easily be smelt, CO has no odour.

Having a gas detector in an RV is an excellent idea. Unfortunately, the sensors for LPG and CO need to be in different locations! LPG detectors must be set low, within 300mm of the floor level. CO detectors, on the other hand, should be at head height for efficient operation.

Gas detectors are often battery-powered, and like smoke detectors, the battery should be checked regularly. The alternative is a 12V connection, which saves the battery charge problem. Gas detectors normally have a test button.

Australian Standard

A benefit of living in Australia, is that the standards for electrical and LPG installations are quite high. They are stricter than many other countries, including surprisingly, the USA. That can give us all a great deal of confidence in how our RVs are wired and plumbed. That doesn't mean though, that we can take everything for granted as we travel around and by taking a few simple precautions, we can all stay safe.

THE NEXT STEP

If you need help choosing your first van or are considering upgrading your existing one, check out all caravans, camper trailers and motorhomes available on TradeRVs today.

The sellers will be happy to help and answer any inquiries you may have about the products advertised for sale.